September 30, 2015 report

Researchers print inside gels to create unique shapes

(Â鶹ÒùÔº)—A team of researchers at the University of Florida has taken the technique of printing objects inside of a gel a step further by using a highly shear-rate sensitive gel. In their paper published in the journal Science Advances, the team describes the technique and the wide variety of objects they were able to print.

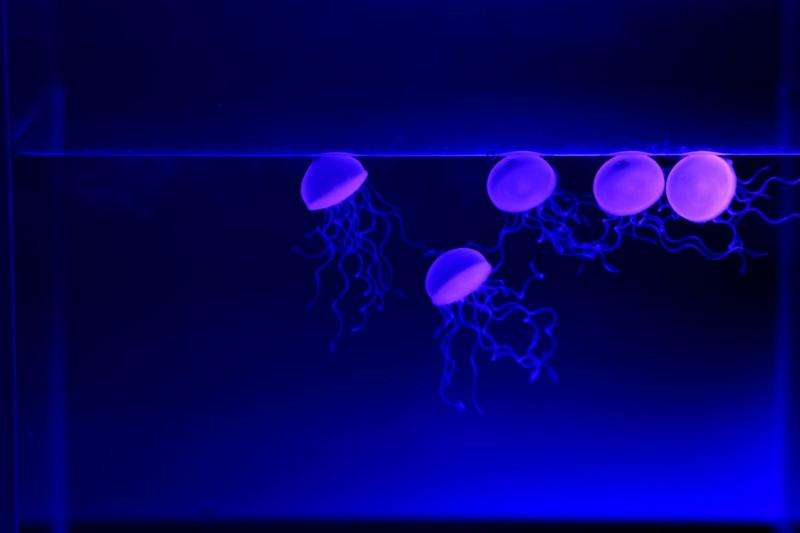

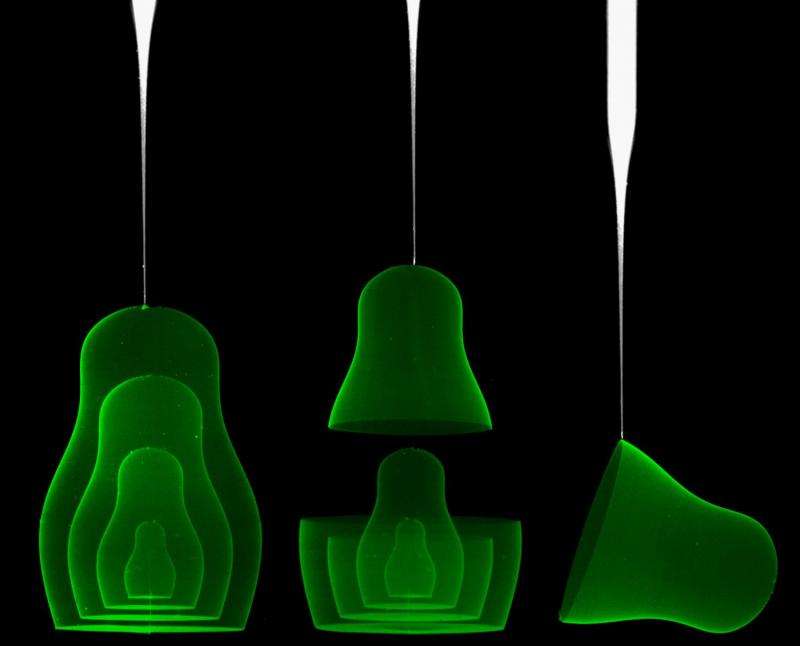

3D printing has come a long way in a short time, objects are now being created around the world in ways unimaginable just a few decades ago. But despite the gains that have been made there is still one problem area: printing objects that tend to collapse during the printing process. Imagine trying to print a jellyfish for example, the material that makes up its body would sag after the first few injections preventing the rest of the creature from being printed. To get around this problem, researchers have been experimenting with scaffolding, and gels. Hard scaffolding only works in very limited applications—gels on the other hand, can be used in nearly limitless ways. They work by holding the object in place while it is being printed. In this new effort, the researchers have refined the process to the degree that they were able to print extremely thin walled closed shells and delicate branched networks.

To improve the process, the team used a commercially available gel made of particles that are just 7µm-wide—that allowed for more precision when printing. To print an object, a gel (the researches describe it as very similar to hand washing gel), is poured into a container, then the printer goes to work—the print-head is shaped like a needle and is dipped down into the gel where "ink" (made of polymers or other materials) is ejected. The ink comes out as a liquid but solidifies as soon as it is ejected into the gel. The printer moves the head around depositing the ink until the object has been completely printed. Once complete the object is pulled from the gel and cleaned.

The researchers suggest that in the future, the technique might be used to print intricate electronics, or more importantly, living tissue, though there is still a long way to go before that can happen—one of the hurdles may be cleanly separating the printed object from the gel.

Journal information: Science Advances

© 2015 Â鶹ÒùÔº