Interfacial-induced fabrication of porous carbon with enhanced intrinsic active sites

Carbon catalysis is an attractive metal-free catalytic transformation, and its performance is significantly dependent on the number of accessible active sites. However, owing to the inherent stability of the C–C linkage, only limited active sites at the edge defects of the basal plane can be obtained even after a harsh oxidation treatment. Therefore, to promote the development of carbocatalysis, it is highly desirable to enhance the density of the intrinsic active sites of carbon from the perspective of the methodology.

Recently, a research team led by Prof. Gang Liu from Jilin University, China developed a facile interface interaction-induced method to fabricate biomass-derived porous carbons (Bio-PCs) with tunable porosity and surface chemistry. In the absence of oxidation treatment, the concentration of oxygen-containing functional groups and the specific surface area can reach 1.27 mmol·²µâ€“1 and 2340 m2·²µâ€“1, respectively, which are significantly higher than those of carbon prepared by traditional hard template methods.

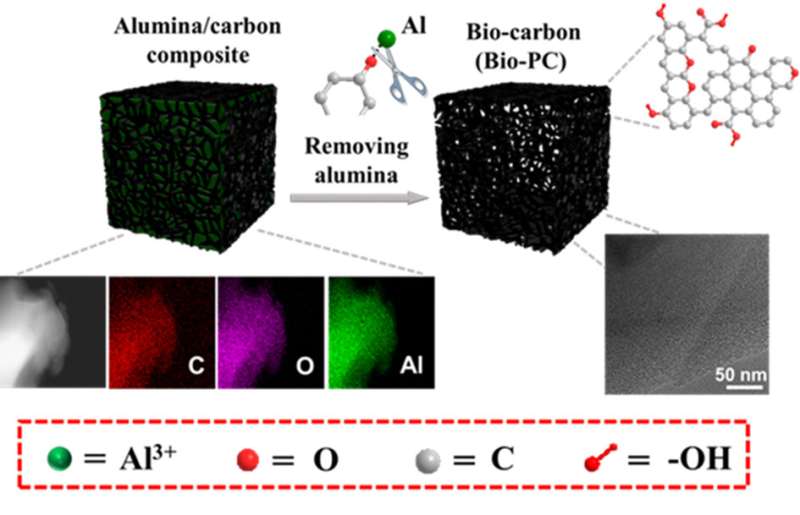

This interface interaction-induced method has two consequent steps and corresponding functions. (1) Al-salts (Al(NO3)3•9±á2O) were firstly blended with biomass precursors (e.g. starch) forming Al-salts/starch interface. The interfacial combustion induced the formation of "more aromatic" carbon structure and alumina/carbon interface. (2) The alumina/carbon interface functioned as a cradle of oxygen-containing functional groups, generating accessible active sites for imine synthesis. The ash content of resultant carbon could be controlled at as low as 0.02 wt%. The yield of carbon calculated with starch precursor is about 14%.

This active carbon shows a significant enhancement in catalytic performance in the oxidative coupling of amine to imine, about 22-fold higher than that of a well-known graphite oxide catalyst. Such interfacial interaction strategies are based on sustainable carbon sources and can effectively tune the porous structure of carbon in the micro- and meso-ranges. This conceptual finding offers new opportunities for the development of high-performance carbon-based metal-free catalysts. The results were published in the Chinese Journal of Catalysis.

More information: Wenjuan Zhang et al, Interfacial-interaction-induced fabrication of biomass-derived porous carbon with enhanced intrinsic active sites, Chinese Journal of Catalysis (2022).

Provided by Chinese Academy of Sciences