Making bone in the lab

Every year there are around 60,000 hip, 50,000 forearm and 40,000 vertebral fractures in the UK. At the Bone and Joint Research Group at the University of Southampton, Professor Richard Oreffo and team have made pioneering advances in the field of bone and tissue regeneration. Last year, a 3D printed hip joint made with a patient's own stem cells was implanted using this technology.

"It should be simple – we know the cell that makes bone (called an osteoblast), but bone is a complex tissue requiring a blood supply and has unique mechanical properties. In addition, the bone stem cell is also extremely rare to isolate," Professor Richard Oreffo, University of Southampton.

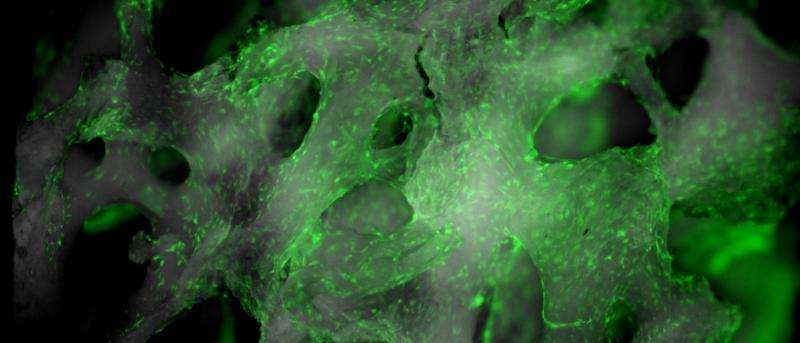

Stem cells are basic tissue building blocks, with a unique ability to become different types of cells. Professor Oreffo and team harness bone stem cells from bone marrow, and differentiate them to become bone, cartilage or connective tissue. This is then combined with a synthetic, 3D printed scaffold to which the cells coat.

The beauty of the team's approach is that it can be custom designed for the patient. There is a place for synthetic implants, but by repairing body with the patient's own tissue, there is less chance of rejection.

With an increasingly ageing population, there are already a number of clinical applications seeing bone marrow cells being applied by orthopaedic surgeons. In 2014, two operations in Southampton were completed using Oreffo's 3D printed hips, and within 5-7 years this could be a simple procedure for patients in the NHS.