Is There a Micro-Supercapacitor in Your Future? Don't Bet Against It

(�鶹��ԺOrg.com) -- A Berkeley Lab scientist was a key member of a team that developed a unique new technique for integrating high performance micro-sized supercapacitors into a variety of portable electronic devices through common microfabrication techniques. Featuring high power densities and rapid-fire cycle times, these new supercapacitors have the potential to substantially boost the performance and longevity of portable electric energy storage devices.

“Just think how often your fancy new mobile phone or computer has become little more than a paperweight because the battery lost its zeal for doing its job,” says John Chmiola, a chemist with the Lawrence Berkeley National Laboratory (Berkeley Lab). “At a time when cellphones can do more than computers could do at the beginning of the Clinton presidency, it would be an understatement to say that batteries have not been holding up their end of the mobile device bargain.”

Chmiola is a staff scientist in the Advanced Energy Technologies Department of Berkeley Lab’s Environmental Energy Technologies Division. His research is aimed at addressing this problem of relatively short-lived portable energy storage devices. Chmiola believes he has found a solution in electrochemical capacitors, which are commonly referred to as “supercapacitors” because of their higher energy storage densities than conventional dielectric capacitors and higher abuse tolerance than batteries.

In a paper published in the April 23, 2010 issue of the journal Science, titled “Monolithic Carbide-Derived Carbon Films for Micro-Supercapacitors,” Chmiola and Yury Gogotsi of Drexel University, along with other co-authors, describe a unique new technique for integrating high performance micro-sized supercapacitors into a variety of portable electronic devices through common microfabrication techniques.

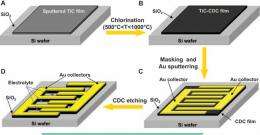

By etching electrodes made of monolithic carbon film into a conducting substrate of titanium carbide, Chmiola and Gogotsi were able to create micro-supercapacitors featuring an energy storage density that was at least double that of the best supercapacitors now available. When used in combination with microbatteries, the power densities and rapid-fire cycle times of these micro-supercapacitors should substantially boost the performance and longevity of portable electric energy storage devices.

“The prospect of integrating batteries and supercapacitors with the micro-electromechanical systems (MEMS) they power represents a conceptual leap forward over existing methods for powering such devices,” Chmiola says. “Furthermore, since the same fabrication processes that produced the devices needing the electrical energy also produced the devices storing that energy, we provide a framework for potentially increasing the density of microelectronic devices and allowing improved functionality, reduced complexity, and enhanced redundancy.”

The two principal systems today for storing electrical energy are batteries and supercapacitors. Batteries store electrical energy in the form of chemical reactants and generally display even higher energy storage densities than supercapacitors. However, the charging and discharging of a battery exact a physical toll on electrodes that eventually ends the battery’s life after several thousand charge-discharge cycles. In supercapacitors, energy is stored as electrical charge, which does not impact electrodes during operation. This allows supercapacitors to be charged and discharged millions of times.

“We have known for some time that supercapacitors are faster and longer-lasting alternatives to conventional batteries,” Gogotsi says, “so we decided to see if it would be possible to incorporate them into microelectronic devices and if there would be any advantage to doing so.”

Chmiola and Gogotsi chose titanium carbide as the substrate in this study because while all metal carbides can be selectively etched with halogens so that a monolithic carbon film is left behind, titanium carbide is readily available, relatively inexpensive and can be used at the same temperatures as other microfabrication processes.

“Plus, we have a body of work on titanium carbide precursor carbons that provided us with a lot of data to draw from for understanding the underlying science,” Chmiola says.

The process started with titanium carbide ceramic plates being cut to size and polished to a thinness of approximately 300 micrometers. The titanium was then selectively etched from one face of the plate using chlorine at elevated temperatures, a process that is similar to current dry-etching techniques for MEMS and microchip fabrications.

Chlorinating the titanium removed the metal atoms and left in place a monolithic carbon film, a material with a proven track record in supercapacitors produced via the traditional “sandwich construction” technique.

“By using microfabrication techniques to produce our supercapacitors we avoided many of the pitfalls of the traditional method,” says Chmiola, “namely poor contact between electro-active particles in the electrode, large void spaces between particles that don’t store charge, and poor contact between the electro-active materials and the external circuitry.”

The electrical charge storage densities of the micro-supercapacitors were measured in two common electrolytes. As promising as the results were, Chmiola notes the impressive figures were achieved without the “decades of optimization” that other electronic devices have undergone. This, he says, “hints at the possibility that the energy density ceiling for microfabricated supercapacitors is, indeed, quite high.”

Adds Gogotsi, “Given their practically infinite cycle life, micro-supercapacitors seem ideal for capturing and storing energy from renewable resources and for on-chip operations.”

The next step of the work is to scale down the size of the electrodes and improve the dry etching procedure for removing metal atoms from metal carbides to make the process even more compatible with commercial microfabrication technology. At Berkeley Lab, Chmiola is working on the development of new electrolytes that can help increase the energy storage densities of his micro-supercapacitors. He is also investigating the factors that control the usable voltage window of different electrolytes at a carbon electrode.

“My ultimate goals are to increase energy stored to levels closer to batteries, and preserve both the million-plus charge-discharge cycles and recharge times of less than five minutes of these devices,” says Chmiola. “I think this is what the end users of portable energy storage devices really desire.”

More information: "Monolithic Carbide-Derived Carbon Films for Micro-Supercapacitors," by J. Chmiola; Y. Gogotsi at Drexel University in Philadelphia, PA; C. Largeot; P.-L. Taberna; P. Simon at Université de Toulouse in Toulouse, France; C. Largeot; P.-L. Taberna; P. Simon at CNRS in Toulouse, France; J. Chmiola at Lawrence Berkeley National Laboratory in Berkeley, CA.

Provided by Lawrence Berkeley National Laboratory